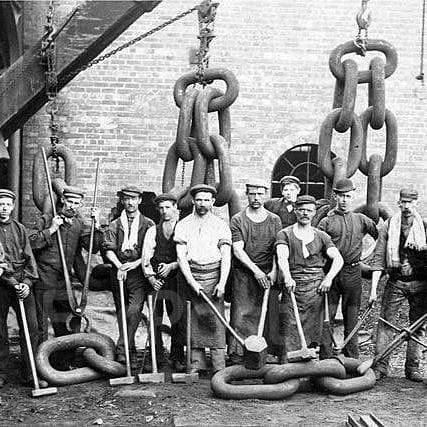

Making the Titanic’s Anchor Chain at Hingley & Sons, 1909

In 1909, the world witnessed one of the most remarkable engineering feats of the early 20th century: the construction of the RMS Titanic. Among the many critical components of the ship, its anchor and anchor chain were manufactured by the renowned English company Hingley & Sons, located in Netherton, Dudley. The process of forging the anchor chain was a testament to the immense skill, precision, and industrial power of the era.

The Manufacturing Process

The anchor chain for the Titanic was an engineering marvel in its own right. Each link of the chain was enormous, weighing hundreds of pounds and requiring expert craftsmanship. The manufacturing process began with selecting the finest quality iron, which was then heated in massive furnaces to reach the necessary malleability for shaping.

Once the iron reached the desired temperature, skilled blacksmiths and metalworkers shaped it into links by hammering and bending it under immense pressure. These links were then welded together using a complex process involving forge welding, where the heated ends of the metal were hammered together to create a seamless bond. The strength of these welds was critical, as the anchor chain needed to withstand extreme forces while securing the Titanic in place.

The Massive Scale of Production

Hingley & Sons had already established a reputation for producing high-quality anchors and chains for some of the largest ships of the time. However, the scale of Titanic’s anchor and chain was unparalleled. The Titanic’s main anchor alone weighed approximately 15.5 tons, making it one of the largest ship anchors ever produced. The accompanying chain measured over 150 fathoms (900 feet) in length, with each individual link weighing around 175 pounds.

The transport of the massive anchor and chain was an event in itself. The anchor was so large that it required a team of horses and a specially designed cart to be transported to the railway station before being delivered to the Harland & Wolff shipyard in Belfast, where the Titanic was under construction.

A Legacy of Industrial Excellence

The work carried out by Hingley & Sons in manufacturing the Titanic’s anchor chain remains a shining example of early 20th-century industrial craftsmanship. It showcased the strength, skill, and technological advancements of British engineering. Although the Titanic met a tragic fate on its maiden voyage in 1912, the efforts and expertise involved in its construction, including the forging of its massive anchor chain, continue to be remembered as a remarkable achievement in maritime history.

Today, the legacy of Hingley & Sons and their contribution to Titanic’s construction is honored through historical exhibitions and records, ensuring that the monumental efforts of these skilled workers are never forgotten.